Equestrians embrace tradition. And, timber frame horse barns offer a time-honored tradition that is hard to beat when it comes to beautiful carpentry exquisitely showcasing the natural aesthetic appeal of wood.

When my husband and I purchased our farmland in Upstate New York, the neighbor had already taken possession of a lovely 2 bridge – or bank – barn in the front of our property. It was still standing proudly on the hill after 100 years, and despite the fact that its main occupants consisted of a flock of pigeons and said neighbor used its 3-story windows as target practice for his golf swing, we did try to buy it.

I was so impressed with the timber peg design, and the huge roughhewn lumber that made up the main part of the structure and I had great plans for its use. The former occupants – a herd of dairy cows – had left the concrete ground level area 10 years before and the building was dilapidated with doors off their hinges and stone retaining walls at the entrances failing. But, to me, the opportunity to own such a lovely, old barn and to bring it back to its former glory was a dream.

Sadly, it remained just that, a dream. The neighbors sold the property and the new owner decided to knock it to the ground and bury it where it stood. No announcement! We looked out the window one day to see a huge wrecking ball bashing it to pieces and our horses galloping around in their paddocks terrified of the commotion.

Fortunately, many timber frame barns have not met such tragic and untimely ends. They have stood the test of time and are highly prized by discerning property owners. Why is that?

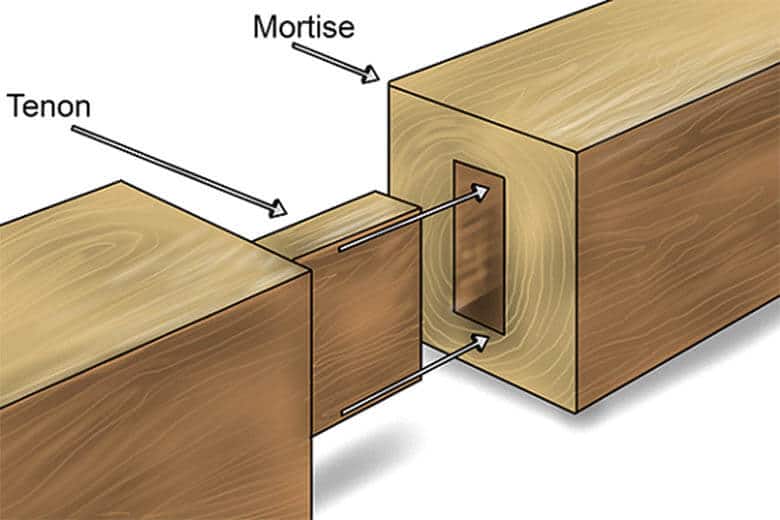

The timber frame construction method encompasses mortise and tenon joinery where a beam – or piece of wood – is pegged on one end and then inserted into a matching hole (or notch) to conjoin solidly with the adjacent piece of lumber.

The work is painstaking because of the craftsmanship and accuracy needed to complete it. Labor costs are necessarily higher, as the journeyman carpenters required must be extremely talented in working with wood and it takes time to produce top quality results.

This type of joinery is revered over the standard post and beam for its inherent beauty, as there is no visual interference to the attractiveness of wood by metal plates or bolts and nails. Timber frame construction also provides the sturdiest and strongest and most enduring type of construction in wooden structures.

As the rafters are cantilevered, the timber frame horse barn also lends itself to having spacious interiors that are free of posts and obstructions. This is one reason that many old timber frame horse barns have been converted to homes.

The raw materials used in timber frame construction are also unique and of premium quality further adding to the cost but with good reason! You can read more about that HERE.

Timber frame buildings are obviously not the cheapest option when it comes to barn construction. But for the discerning horse owner that wants to step it up a notch (pardon the pun), the advent of a unique combination of a modular horse barn configured with timber frame construction does minimize the sticker shock. This innovative combination design is less expensive than a straight timber frame build completed on site.

Another factor to consider when it comes to purchasing a new barn, is the time needed for construction and the noise, mess and general stress than can be involved.

The advantage of this ‘revisited’ timber frame horse barn is the modular components that form the ground level of the building. These barn ‘modules’ are made in the factory and delivered prebuilt directly to the site. Stalls, doors, windows – all the interior features – are assembled and ready to have the magnificent timber frame second floor loft (and lean-to/overhang if purchased) added on site to complete the barn.

This saves time as the construction is not delayed by inclement weather or material shortages/deliveries. It also ensures a quality controlled product that is not hampered by crews that haven’t worked together before or don’t have the experience in the world of horsemanship.

Consider the concerns horse owners have about dropped nails on site, and worries of interruption of their peace and quiet for riding/training on the property and the disruption of construction noise as issues that can all be significantly reduced.

While a timber frame/modular combination building is not going to be quite as ‘instant’ a new barn on the farm as a standard modular horse structure, the delivery and set up of the final barn is only, on average, about 4-5 days longer.

The traditional timber frame is indeed revisited, with modern day improvements that can mitigate both the price and the construction time and fuss. Look for a company that offers a proven positive customer service experience, provides warranties and ‘to the penny’ pricing to ensure the barn purchase is a happy event from start to finish.

Everything old is new again. Sometimes, the traditional methods are the best!