When it comes to building a new barn the quality and complexity of plans run the gamut from elaborate architect drawn designs to renderings drawn by hand by a keen horse owner or neophyte construction personage.

Making sense of barn plans is essential if the outcome of the build is to match the intended design. The level of detail the drawing plans will entail will likely be a combination of what is minimally required by the local building code office for permits and what the construction company intends to complete.

Bear in mind some towns have no requirement for permitting at all particularly for agricultural buildings. As no-one is supervising the details of the plans or the construction design, this can be a huge negative for the property owner that is making a barn purchase, whether it is to be constructed on site as a stick-built or pole barn structure or delivered as a modular ‘instant’ build.

Be aware that poor building practices are sometimes done by property owners with full knowledge of the shortcomings of the design. Unfortunately, knowledge of these issues is not always passed along to an incoming buyer of the farm. For example, an indoor arena or barn with a low pitch roof may be cheaper to construct than one that is properly rated for the snow and wind load. The property owner may knowingly choose this option and plan to shovel the snow load off the building during heavy snowfall to mitigate the risk of roof collapse, but the incoming new owner may be unaware of the issue. Building codes are there to protect everyone and should not be overlooked.

Meeting code requirements in construction of the barn regardless of whether they are mandated or not is an essential protection for the barn purchaser and buyers should not be afraid to ask for review of plan designs by their local building code officer even if permits are not required. These qualified individuals are a valuable resource and their knowledge can be a sincere effort in the barn buying process.

Outside of the level of intricacy the building plans must define for the permit process, if the property owner understands the factors that should always be included in building plans this can go a long way to ensuring that the final build matches their envisioned horse barn and avoid disappointments in materials used and the quality of the construction. Even in areas where no plans are required, having plans at hand to define the parameters of construction is a good idea.

Drawn from the two perspectives of the construction company and the building code requirements the plans can be submitted via various methods. Electronic submissions of CAD or similar software developed plans is quick and easy to do where it is accepted by the local authorities, and hard print copies can easily be provided for use on the job site and for owner approval. While not as high grade, plans that are hand drawn with pen and ruler can also work if the barn is a simple design such as a run-in shed or two stall shed row.

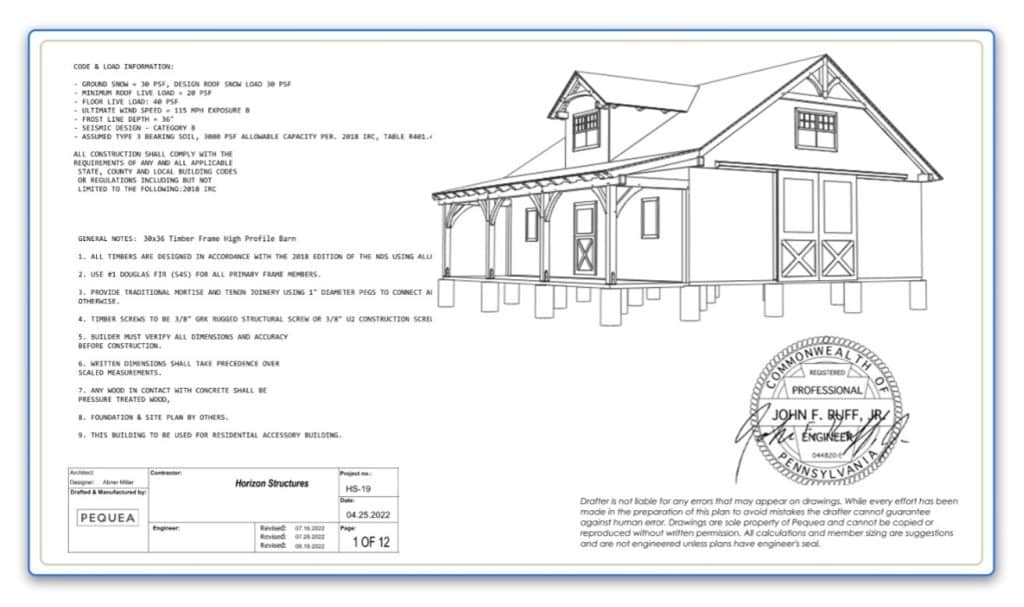

Some building codes require that the building plans be certified and stamped by a qualified engineer. This all important ‘stamp’ indicates that the structural integrity of the design has been reviewed by a professional and approved as safe and meeting certain codes for wind and snow loads and that the build itself is adopting commonly accepted building practices and materials.

However, not any stamp or certification will do. It is important that the stamp provided is issued in accordance with the regional requirements of your State and exact location. For example: a set of plans for a center aisle barn to be sited in hurricane prone Florida will not require the same parameters in its construction detail as the identical building sited on a snow laden New Hampshire hilltop.

The certification of plans by a licensed engineer offers the property owner important assurance that the barn will be properly built to provide safe use and to be durable.

Companies that construct horse barns on a national level are aware of regional requirements and changes in Federal and State building codes that may affect the plans and will follow directives with accuracy that minimizes delays in the permit issuance process.

Often these larger companies employ their own drafting professionals who can adjust their myriad of in-house barn designs to accommodate any need. Whether that need be a specification that a particular building inspector requires or a custom upgrade that the barn purchaser wants to make. Where it is allowed by the State laws, such companies can liaise directly with the town building department through initial submission to full approval and permit issuance for a build on behalf of the property owner.

Certification and issuance of the all-important ‘stamp’ will necessarily incur additional costs than plans that have not been through this review process. In the planning stage of the barn building project and before purchase of a structure, prospective barn owners should be sure to ask what extra fees may be incurred for certification of plans. Fees that may be charged range from just a few hundred dollars to $10,000+, so it pays to get this quoted in writing up front before making a deposit on a new barn build.

Regardless of who is providing the building plans and the level of complexity the barn owner is willing to accept, even the most minimal construction project should not be undertaken without provision of basic design plans. These should include profile drawings for all four sides of the structure, floor plans for each level and a site map.

Aside from the obvious advantage of mapping out the design of the structure and its construction details, plans also serve to provide an important visual aid for the purchaser where the style and aesthetic appeal of the building can be reviewed.

It is wise to note that structures often appear smaller on paper or on a screen than in real life. Even with 3D renderings of a barn the size and stature of the structure can be hard to gain perspective about unless some size known comparative building or object is drawn to the same scale.

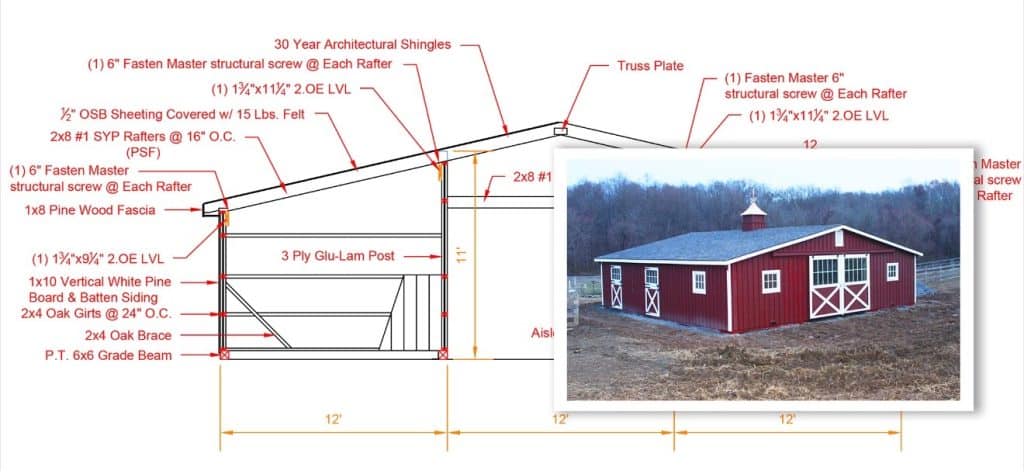

Dimensions for all structural lumber and their exact placement distances O’C’, meaning on center, and sizes of all doors, windows and stalls should be noted together with materials to be used and the plans drawn to scale with a legend included. Examples: grade #2, 6” x 6” x 12’ ground contact pressure treated lumber, 25-year asphalt shingle over a ¾ inch tongue and groove plywood sheeting, grade # 2 2” x 4” x 12’ Douglas Fir or Cypress. The type of joinery at key points such as bolted or mortise and tenon, rafter tie sizes and type etc. should all be defined.

The site plan should define what aggregate materials should be used across the levelled site, to what depths they should be laid and whether compaction is required. Larger structures may require special drainage provisions and positioning and specifications for any pillars to be installed for structural support or a concrete foundation.

As drainage considerations or subsidence that may be caused by water or run-off are an important part of any building’s integrity, this factor is better addressed at the outset of the build rather than down the road. It is much easier to create a drainage apron around the building, excavate for footer drains if needed and then backfill than to dig up the area surrounding the barn later to fix a problem. Correctly installed gutter systems are an important component of construction that ensures run-off from the roof is properly dispatched away from the foundations of the structure.

It is also a good idea to define on the plans or the supporting purchase document whether substitution of materials is acceptable. While it may be necessary due to local availability to switch up a Douglas Fir member to a Cypress wood without compromising the quality of the build, substituting an off-brand siding material for a name brand with full warranties can make a world of negative difference in future years.

Substitutions are a great way for a manufacturer or builder to cut costs. Budget constraints may determine that the property owner wishes to go along with lesser quality or lesser warrantied products, but it is wise for the purchaser of the building to be aware of the differences between products so they can make an informed decision.

Ensuring your barn building project goes as smoothly as possible means having everyone on the same page. The property owner, the construction company and their crew, and the local building inspector.

Collaboration from the outset along clearly defined lines is the best method to mitigate upsets with building delays, shoddy workmanship, and unexpected budget overrides caused by work order changes mid project.