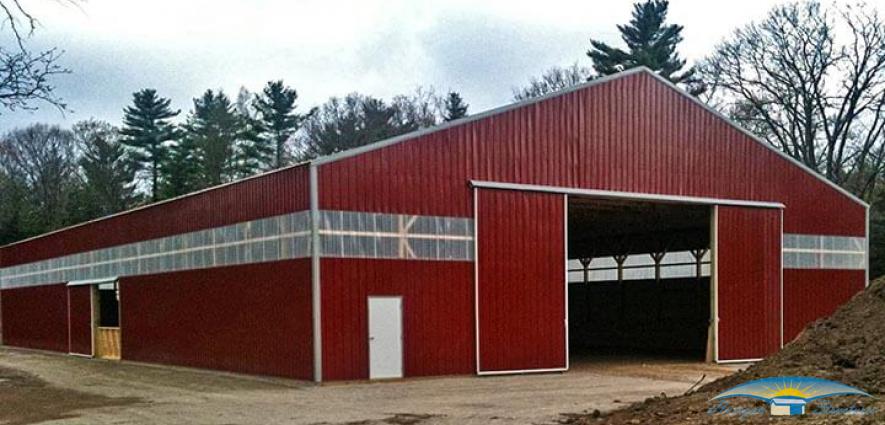

Farm owners: Boarders and other folks seeking your equine training/breeding/etc. services will pick your stable over another if you’ve got an indoor arena to offer. A covered, indoor horseback riding arena is a huge asset to your equine operations.

An indoor horse arena is a large project and a significant expense to be sure but one that will pay off in enormous advantages and benefits in the long run. Indoor riding arenas offer safe, controlled environments to ride and train year round regardless of weather conditions. Horses, riders and trainers stay focused, as outside distractions are reduced. The first step in a covered horse arena project starts with research. And…. you’ve started in the right place!

Olympic Equestrian, Boyd Martin, Shares His Thoughts on Indoor Arenas

Why We Like Wood Frame Construction

- Engineered plans that meet current codes.

- The right sized Glue Lam Poles not undersized solid sawn lumber.

- ROBUST truss bracing. Correctly spaced and designed to meet local snow load specs.

- Licensed truss designer with 20+ years of experience.

A wide-span building is no place to take risks. Err on the side of safety when designing for the weight bearing capacity of our covered horse arena roofs. Choose a construction company that builds for the varied snow loads in their service area and then add extra support to make their indoor arenas a safe place to ride any time of year!

Steel Frame Arenas vs. Wood Frame Arenas

STEEL FRAME

- Can go wider than 90'

- More expensive

- More costly and difficult to insulate

- Longer build time

- Construction time is seasonal

WOOD FRAME

- Up to 90' wide

- Less expensive

- Easier and cheaper to insulate

- Faster construction time

- Able to build throughout the year

Size

The minimum width for an indoor riding arena is 60′. Anything less is probably going to be too small. The average width for an indoor horse riding arena is 70′ to 80′.

The optimum length can vary widely depending on your discipline; however, covered riding arenas falling within the 120′ to 250′ range are the most common.

Standard interior height is 16′ to 18′ to the top of the trusses.

The most common indoor horse riding arena sizes are: the 60′ wide x 120′ long and the 80′ wide by 200′ long. It’s important to have a clear-span structure meaning no posts or beams inside the arena’s riding areas. If you’ll be riding in groups or training, a longer indoor arena is advisable. The most common height in a covered horse arena is 16 feet high. But for jumping, we usually advise folks to go another 2 feet, or 18 feet high. Any height over 18 feet is more for a commercial/professional horse arena.

Doorways should be between 12 and 14 feet high, to allow overhead clearance for a mounted rider, and 16 feet wide.

Remember: Bigger horse arenas have extra “hidden” costs: more lighting, more footing and more real estate.

Options:

Check the list below and ask to have these items included in your estimate!

Cupola: One cupola, or several, will give your indoor arena a finished look from the outside. Also useful for providing ventilation.

Doors: Large sliding doors to accommodate a mounted rider or large equipment and “man doors” – add what you want where you want it to make getting in and out of your horse arena as easy and convenient as possible.

Rain Gutters: Divert rain water and snow melt away from your covered riding arena to keep the doorways and high-traffic areas from becoming swampy mud holes.

Rider Guard: Provide safety in addition to a finished look to the interior of your riding arena. Creates space between the vertical framing of the wall and the horse’s hooves which, in turn, creates space between the wall and the moving horse for the rider’s stirrups and knees.

Side Lights: A cost-effective way to bring natural light into your covered riding arena. Side lights can be less expensive and easier to install than sky lights. Side lights can be designed to be two times the size of a sky light and can bring in twice the amount of light. Additionally, side lights eliminate the fire risk of electrical lighting.

Sky Lights: For even more light, consider adding some sky lights along the roof. Stalls: What could be more convenient than having access to your indoor arena directly from your barn? Create the ultimate multi-purpose covered riding arena with stalls.

Vapor Barrier: An insulated roof can help with the acoustics, reduce noise, cut down on the hot-house effect and limit condensation.

Wainscoting: Vary the appearance of the arena walls by adding wainscoting half way up and choosing an alternative color for the remainder of the wall.

How Much Does It Cost?

Our indoor horse riding arenas for sale have prices that can vary greatly depending on size, options, add-ons, and a number of other factors.

Buyer Responsibility

Your custom indoor riding arena Amish builder will supply the materials and labor to build your indoor horse arena on site. This is very important to remember when comparing indoor riding arena prices! It normally takes builders three weeks to complete most arenas – weather permitting. Prior to the arrival of building crew, you are responsible for the site prep and leveling. You’ll also need to determine what kind of equestrian footing you want for your arena.

*Most of customers use mulch, sand or ground up rubber.

Insider Tips

Location: The first and most critical step in building an indoor riding arena is selecting the proper location. Making a mistake here can add up to extra costs for excavation, arena footing and additional site prep measures.

Choose a site that is already as level as possible. This will reduce the amount of excavation and site prep needed. If you’re lucky enough to have a relatively level area without having to remove too many trees your savings will be significant. Research shows that building your indoor arena too close to a tree line can cause compaction of the soil that will likely kill the trees. And, you certainly don’t want to risk the chance that strong winds could uproot trees and send them crashing through your arena roof!

Another advantage of having a level spot is that you won’t have to worry about water runoff from surrounding hills. Keep in mind an area that accumulated water before you begin building the covered horse arena will probably do so after it is constructed.

This leads to the question of drainage in your selected spot. If you’re forced to build in a spot where you’ve got to level the area you’ll also need to construct drainage channels around the arena. The alternative is to build up the area where the horse arena is being built. The idea is to divert water around and away from your riding arena rather than having it run right through the middle – taking the footing along with it!

Moisture is best removed by percolating into the ground below the indoor arena footing. A general rule of thumb is that for every inch of rain on an arena, it should take 24 hours for it to dissipate to a point where riding is safe again. Take this into consideration when researching and choosing your arena footing. Building an indoor riding arena is a series of compromises. There is no such thing as a “perfect” arena. It’s too big or too small, too narrow or not long enough, too close to the barn or too far away. There is always something not perfect about the footing or drainage. Scapegoats are a dime a dozen when it comes to covered riding arenas. Ultimately, you may find your arena is too dusty or too wet or just a tad slippery or the wrong color. The more research and careful planning you do up front will get you closer to the ideal covered horse arena you’ve dreamed of.

Take Time to Plan. Building an indoor riding arena isn’t something you want to have to do over. Ask yourself what you want, and then ask yourself what you really need and can afford.

Aside from your equine related activities, consider other income producing sources for your building by leasing out arena time to interests outside the horse industry. For example, a local dog trainer wants to run agility classes at a time you don’t use the arena. Or a group of neighborhood walkers and runners like the idea of being “indoors”, but not in a gym. No matter what the new uses may be, be sure to include your insurance agent in early discussions to know how any of these changes will impact your liability policy.

Other uses for covered arenas for sale include heavy equipment storage, sport courts or warehouse space.

We do not sell indoor riding arena kits. For smaller products like chicken coops, garden sheds or run-in sheds, a kit is fine. However, it’s our experience that indoor riding arenas are large, complex projects using materials and equipment requiring special handling skills and; therefore, not suitable for do-it-yourself kits.